Table of Contents

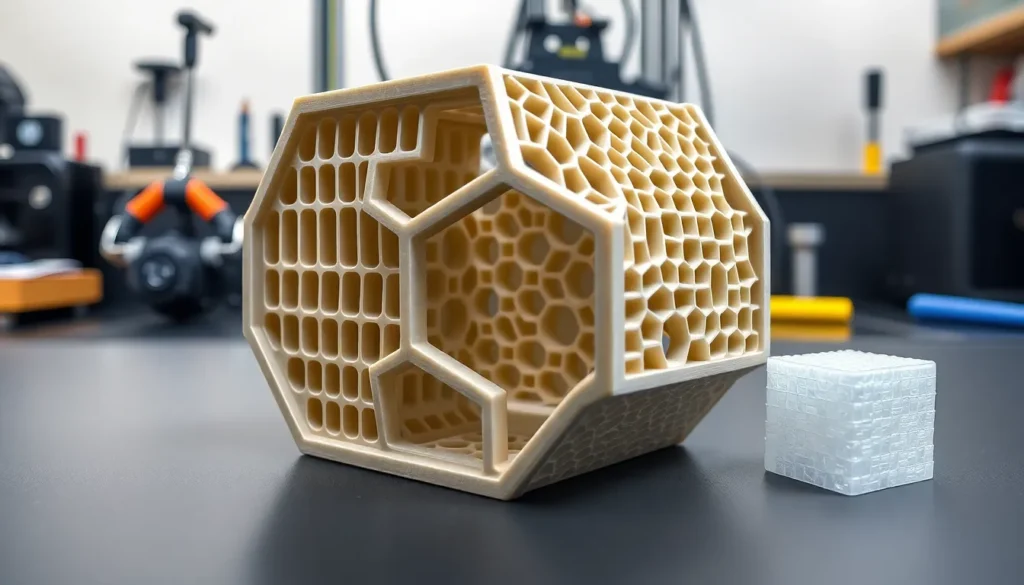

ToggleIn a world where creativity knows no bounds, 3D printer experimentation is the playground for innovators and tinkerers alike. Imagine transforming a wild idea into a tangible object right before your eyes. It’s like magic, but with a little more math and a lot less wand-waving. Whether it’s crafting quirky gadgets or solving real-world problems, 3D printing has become the ultimate tool for those who dare to think outside the box—or rather, inside the printer.

Understanding 3D Printer Experimentation

3D printer experimentation involves exploring new techniques, materials, and designs through additive manufacturing. This process not only fosters innovation but also reveals the vast possibilities within the realm of 3D printing.

Definition and Importance

3D printer experimentation refers to the practice of testing various approaches in the 3D printing process. This exploration allows users to expand their skills, refine their designs, and discover unique functionalities. Innovation thrives on experimentation as it encourages solutions that can address specific problems. By taking risks in design and technique, individuals and companies enhance productivity and creativity, leading to breakthroughs in their respective fields.

Applications in Various Industries

3D printing finds application across several industries due to its versatility. In healthcare, it creates customized prosthetics and implants tailored to individual needs. The automotive sector utilizes 3D printing for rapid prototyping, allowing for quicker tests and adjustments. Aerospace companies benefit from lightweight components that reduce fuel consumption and increase efficiency. Additionally, education incorporates 3D printing to provide hands-on learning experiences, fostering skills in engineering and design. Each application underscores the transformative impact of 3D printing in shaping future innovations.

Types of 3D Printing Technologies

Various 3D printing technologies cater to different needs and applications. Understanding these methods enhances experimentation and innovation.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling stands as one of the most popular methods in 3D printing. This technology utilizes thermoplastic filaments, which melt and extrude through a nozzle to build layers. Common materials include PLA and ABS, known for their accessibility and versatility. Accuracy levels in FDM can reach 0.1 mm, which supports intricate designs. Users often appreciate the cost-effectiveness of FDM printers, making them ideal for hobbyists and educators. Various industries, from prototypes to functional components, leverage FDM technology for its reliability and ease of use.

Stereolithography (SLA)

Stereolithography employs a different approach, utilizing ultraviolet light to cure liquid resin layer by layer. This method achieves high precision and smooth surfaces, with details as small as 25 microns. Popular in jewelry design and prototyping, SLA shines in applications that demand fine detail. A range of resins exists, catering to diverse requirements, including flexibility and durability. Users benefit from fast print speeds compared to other techniques, which accelerates the design process. In industries such as healthcare, SLA’s capabilities help create detailed anatomical models and dental fittings.

Materials Used in 3D Printer Experimentation

A variety of materials play a crucial role in 3D printer experimentation. The choice of material significantly influences the properties and applications of the final printed object.

Commonly Used Filaments

PLA remains one of the most popular filament types due to its ease of use and biodegradable properties. ABS is another choice favored for its strength and durability, often used in making functional prototypes. PETG combines the best of both PLA and ABS, offering excellent toughness and chemical resistance. Nylon presents itself as an option for high-strength applications, ideal for mechanical parts. TPU, a flexible filament, enables the production of soft and elastic items, like phone cases and custom grips.

Emerging Materials for Experimentation

Innovators are increasingly experimenting with advanced materials, pushing the boundaries of 3D printing. Composite filaments, infused with materials like carbon fiber or metal, enhance strength and reduce weight, making them suitable for aerospace applications. Bio-based filaments derived from materials like algae and cellulose are gaining traction for their sustainability. Ceramic filaments allow for high-temperature applications and artistic endeavors, offering a unique aesthetic. Conductive filaments are opening new possibilities in electronics, enabling the creation of functional electrical components.

Experimentation Techniques and Best Practices

Experimentation with 3D printing requires strategic approaches to design and settings. Implementing best practices enhances the potential for success and innovation.

Design Considerations

Designing for 3D printing involves understanding the unique characteristics of the medium. Designers must consider factors like layer adhesion and overhangs. Optimizing geometry improves strength and reduces material use. Incorporating supports where necessary ensures printability of complex structures. Exploring different design software can offer a range of tools that streamline the process. Utilizing 3D modeling software specifically suitable for printing helps visualize the final product. Prioritizing functionality and aesthetics can lead to a well-rounded design.

Calibration and Settings

Calibrating a 3D printer is essential for ensuring high-quality prints. Regularly checking nozzle height is crucial to achieving the ideal first layer. Adjusting temperature settings for different materials affects consistency and adhesion. Fine-tuning print speed can minimize defects and enhance detail. Exploring different infill percentages impacts the strength and weight of the final product. Checking and adjusting bed leveling contributes to better layer adhesion. Using slicer settings tailored for specific applications improves overall outcomes.

Challenges in 3D Printer Experimentation

Experimenting with 3D printing presents several challenges that users frequently encounter. Addressing these issues enhances the overall quality of printed objects and expands creative possibilities.

Common Issues and Solutions

Print quality often suffers due to common problems like layer adhesion and warping. Adjusting the bed level and maintaining proper temperature settings can significantly improve outcomes. Users frequently deal with filament jamming, which can interrupt the printing process. Regularly cleaning the nozzle and using high-quality filament reduces this risk. Calibration errors also affect dimensional accuracy. Employing test prints and refining the printer’s settings corrects these inconsistencies, ensuring better results.

Overcoming Material Limitations

Material selection directly impacts print quality and functionality. Filament properties influence adhesion, flexibility, and strength. Users experience challenges when working with materials like Nylon or TPU, which require specific print settings. Ensuring the right temperatures and conditions helps mitigate these issues. Experimentation with new materials often presents difficulties in compatibility with existing hardware. Testing small amounts of new filaments allows users to discover optimal settings before committing to larger projects. Engaging with communities or forums can also provide valuable insights on overcoming these material challenges.

3D printer experimentation opens doors to endless creativity and innovation. By embracing new techniques and materials, individuals can push the boundaries of what’s possible in additive manufacturing. The ability to transform concepts into tangible objects not only fuels personal growth but also contributes to advancements across various industries.

As users navigate the challenges and triumphs of 3D printing, they’ll discover a community rich with knowledge and support. This journey of experimentation not only enhances skills but also leads to unique solutions that can change the way we approach design and production. With every print, there’s an opportunity to learn and innovate, making 3D printing an exciting frontier for creators everywhere.