Table of Contents

ToggleIn the quirky world of 3D printing, layer height is the unsung hero that can make or break a project. Imagine trying to bake a cake with the wrong measurements; it’s a recipe for disaster! Just like that, choosing the right layer height can mean the difference between a smooth, stunning print and a wobbly mess that looks like it survived a hurricane.

Understanding Layer Height 3D Printing

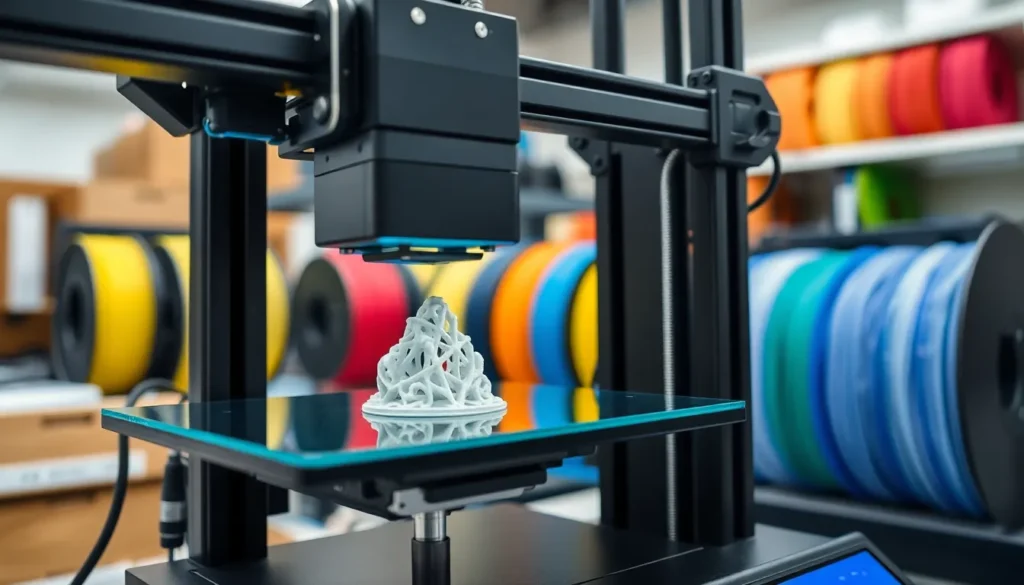

Layer height plays a pivotal role in the quality of 3D prints. It refers to the thickness of each layer deposited during the printing process and influences several aspects of the final product.

What Is Layer Height?

Layer height represents the vertical distance between successive layers in a 3D printed object. Common values range from 0.1 mm to 0.4 mm, with some printers supporting even finer settings. A smaller layer height delivers increased detail in prints, while larger values expedite the printing process. Knowing the specific layer height needed for a project ensures that the desired finish aligns with expectations.

Importance of Layer Height in 3D Printing

Layer height significantly affects print resolution and surface quality. A fine layer height enables precise details, making it ideal for intricate designs or decorative items. Conversely, a thicker layer height reduces print time and is better suited for simpler, larger objects. The choice between these options influences not just aesthetics but also structural integrity. Each layer’s thickness impacts the strength of the printed model, requiring careful selection based on the project’s aims.

Effects of Layer Height on Print Quality

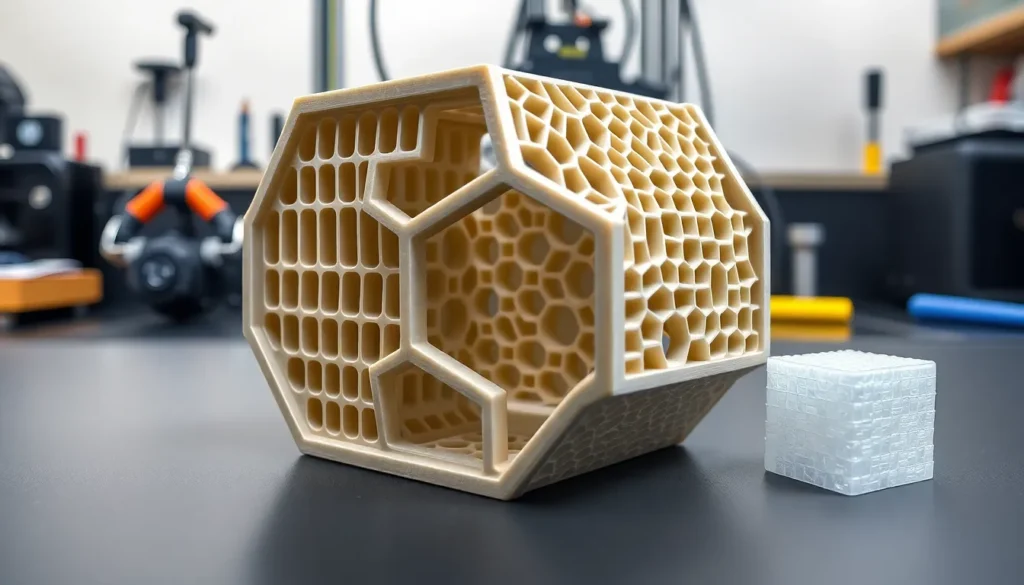

Layer height significantly influences various aspects of print quality, impacting both aesthetics and functionality. Understanding its effects can guide optimal choices for specific projects.

Surface Finish

A smaller layer height typically yields a smoother surface finish. Prints created with a height of 0.1 mm exhibit fewer visible layers, enhancing the overall appearance of intricate details. In contrast, a larger layer height of 0.3 mm or more can lead to noticeable layering and a rougher finish. This texture may suit certain applications, but smoothness often becomes essential for final products where touch and visual impact matter. The interplay between layer height and other settings, such as print speed and nozzle size, also plays a crucial role in achieving desired surface quality.

Detail Level

Detail level increases with reduced layer height. A measurement of 0.1 mm allows the printer to replicate fine features with accuracy, making it ideal for small, complex designs like figurines or architectural models. Larger layer heights, such as 0.4 mm, diminish detail visibility, suitable for simpler geometric shapes or prototypes. As print resolution improves, it’s important to balance detail with time efficiency. For instance, intricate parts may necessitate longer print times, while larger, less complex models can benefit from expedited production without sacrificing overall quality.

Recommended Layer Heights for Different Applications

Choosing the right layer height streamlines the 3D printing process, optimizing both aesthetics and functionality. Different applications require specific considerations for layer thickness.

Common Practices for Various Materials

PLA, a popular 3D printing material, typically performs best at layer heights of 0.2 mm. This balance provides excellent detail without excessive print time. For ABS, optimal layer heights range from 0.2 mm to 0.3 mm, enhancing strength while accommodating its notorious warping tendencies. PETG, known for durability, works well at 0.2 mm, maintaining quality and speed. Flexible filaments often require a layer height of 0.3 mm to ensure proper adhesion and print quality. Each material brings unique challenges, making adherence to these practices essential for achieving desired results.

Layer Height for Functional Prototypes

Functional prototypes benefit from strategic layer height selection. A height of 0.2 mm provides a good compromise between detail and durability, suitable for a wide range of applications. When precision is paramount, reducing the layer height to 0.1 mm enhances detail for intricate designs. In contrast, simpler prototypes can utilize 0.3 mm or 0.4 mm heights for faster production, saving valuable time without compromising functionality. Adapting the layer height to the specific requirements of the prototype ensures that performance objectives are met effectively.

Choosing the right layer height in 3D printing is essential for achieving the desired quality and functionality of a printed object. Each project demands careful consideration of layer thickness to balance detail and efficiency. Whether aiming for intricate designs or faster production, understanding how layer height impacts surface finish and structural integrity is key. By aligning layer height with material properties and specific application needs, creators can optimize their prints for both aesthetics and performance. This strategic approach ensures that the final product meets both visual and functional expectations.