Table of Contents

ToggleEver wondered how long it takes to turn a digital dream into a tangible reality? 3D printing might just be the magic trick you didn’t know you needed. But hold on to your filament, because the answer isn’t as straightforward as it seems. From intricate designs to the type of printer used, various factors can stretch or shrink the timeline like a rubber band.

Factors Influencing 3D Printing Time

Several factors significantly affect 3D printing time. Understanding these elements helps users estimate how long a print job might take.

Model Complexity

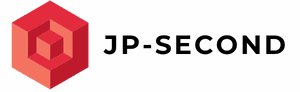

Model complexity plays a critical role in determining print duration. Intricate designs with numerous details require longer printing times compared to simpler shapes. Each additional feature or higher level of detail increases the number of layers needed, which contributes to extended printing periods. For example, a basic cube might print in under an hour, while a detailed figurine could take several hours due to its intricate geometry. Ultimately, more complex models demand more attention from the printer, slowing down the overall process.

Print Resolution

Print resolution impacts the fidelity of the 3D-printed object and the time it takes to complete. Higher resolutions produce finer details but increase the printing duration. This is due to the printer making more passes to achieve the desired finish. Lowering the resolution can speed up the process, but this often sacrifices detail and surface quality. A resolution setting of 0.1 mm usually takes longer than one set at 0.3 mm. Evaluating the necessary details against the desired timeline can help in selecting the right resolution.

Material Type

Material type also affects how long 3D printing takes. Different materials have varying melt temperatures and flow characteristics, influencing the speed of the print. For instance, ABS filament typically prints faster than more viscous materials like TPU. Additionally, some materials require specific print settings, which may prolong the process. Understanding the properties and requirements of each material enables users to optimize print time while ensuring quality. Various testing with multiple materials can help establish the most efficient choice for specific projects.

Different 3D Printing Technologies

3D printing encompasses various technologies. Each method influences time and production details.

FDM Printing

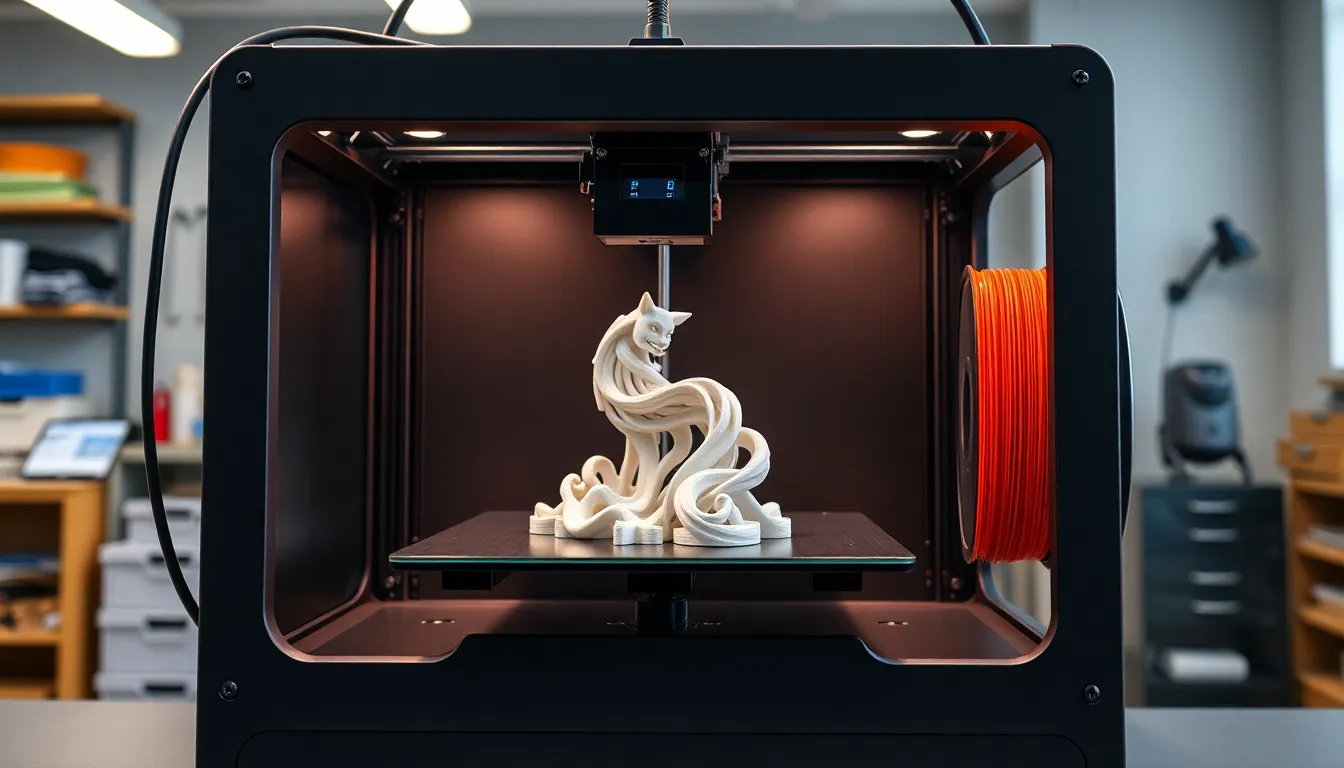

Fused Deposition Modeling (FDM) uses melted thermoplastic filaments to create layers. Typically, FDM printers are popular for prototyping and low-cost production. Printing speed ranges from 30 to 300 millimeters per second, depending on the complexity of the model. Layer height affects quality; thinner layers lead to longer print times while thicker layers result in faster prints. Material types also vary, with PLA and ABS being the most common. He also highlights that FDM produces less visible layer lines, enhancing surface quality.

SLA Printing

Stereolithography (SLA) works differently by using a UV laser to cure photopolymer resin. This method excels in producing high-resolution prints with intricate details. Printing speeds average around 20 to 80 millimeters per hour, influenced by layer thickness and part complexity. SLA offers exceptional surface finishes, so thinner layers yield superior quality, although at the cost of speed. It often requires post-processing steps, like washing and curing, which add to the overall time. Users benefit from a range of resin materials, optimizing for desired properties like flexibility or strength.

Estimating Print Time

Estimating 3D print time involves analyzing multiple factors that contribute to the duration of a project. Users can gain more accurate predictions by considering these elements.

Using Slicing Software

Slicing software plays a vital role in determining print time. This software translates 3D models into instructions for the printer. Users input parameters like layer height, print speed, and infill density. Those settings directly influence how long a print task takes. Most slicing programs provide estimated print times based on these parameters. Adapting these variables can significantly affect project timelines, allowing for adjustments based on specific requirements.

General Guidelines for Various Models

General guidelines for different models offer users insight into expected printing durations. For simple shapes, print times usually range from a few minutes to several hours. Conversely, complex models can take from several hours to even days to complete. As a reference, models created using FDM technology typically print faster than those produced with SLA, given the differences in speed and layer curing. Keeping an eye on characteristics like model size and detail helps in setting relevant expectations. By understanding these guidelines, users can better plan their printing schedules.

Real-World Examples

Understanding how long 3D printing takes in practice requires examining specific instances of both simple and complex models.

Simple Models

Simple models often print quickly, typically needing just minutes to a few hours. For example, items like basic brackets or keychains can be completed in under an hour when using Fused Deposition Modeling (FDM) technology. Layer height and print speed greatly influence this duration, with higher speeds yielding faster results. Many users report achieving satisfactory outcomes with average infill settings and moderate layer heights. Quick setups make these projects appealing for both beginners and experienced users. Rapid prototyping opportunities abound when working with straightforward designs, making them highly suitable for quick testing and iterations.

Complex Models

Complex models demand significantly more time to print, often ranging from several hours to multiple days. Intricate designs, such as detailed sculptures or functional mechanical parts, require fine layer heights to capture specific features. Users often choose Stereolithography (SLA) for these projects due to its high-resolution capabilities, despite slower printing speeds. Many factors, including support structures and material properties, also add to the overall time involved. Planning and patience are essential when tackling complex projects, as post-processing requirements further extend production timelines. Ultimately, understanding these factors helps users allocate appropriate time to ensure quality results.

3D printing is a fascinating process that requires careful consideration of various factors that influence the time taken to produce a final product. From the complexity of the design to the type of technology and materials used, each element plays a crucial role in determining print duration.

By understanding these factors and utilizing appropriate techniques, users can optimize their printing schedules while ensuring high-quality outcomes. Whether it’s a quick prototype or an intricate model, effective planning and patience are essential to achieving the desired results in 3D printing.