Table of Contents

ToggleIn a world where everything from toys to car parts can be whipped up in a 3D printer, many people wonder: just how much does this magical technology cost? It’s like asking how much a unicorn costs—there’s a range, and it depends on what you’re dreaming up. From budget-friendly home printers to industrial machines that could probably print a small spaceship, the price tags can vary wildly.

Understanding 3D Printing Costs

3D printing costs vary significantly based on multiple factors. Initial investment and ongoing expenses contribute to the total financial commitment.

Initial Setup Costs

Initial setup costs encompass the purchase of the 3D printer and necessary accessories. Basic home models often start around $200, while professional-grade printers can exceed $10,000. Additional expenses include filament storage, software licenses, and maintenance tools. These components elevate the upfront investment but typically ensure optimal functionality. Potential buyers should account for the printer’s capabilities when budgeting.

Ongoing Material Expenses

Ongoing material expenses primarily involve the cost of printing filament. Prices for filament vary depending on the material. PLA and ABS filaments typically range from $20 to $50 per kilogram. Specialized materials like nylon or TPU can cost $70 or more per kilogram. Regular printing usage may generate higher material expenditures over time. Users should also consider replacement parts, such as nozzles, which may incur extra costs based on printing frequency.

Factors Influencing 3D Printing Costs

Various elements impact the overall costs of 3D printing. Understanding these factors can help users make informed decisions about their printing needs.

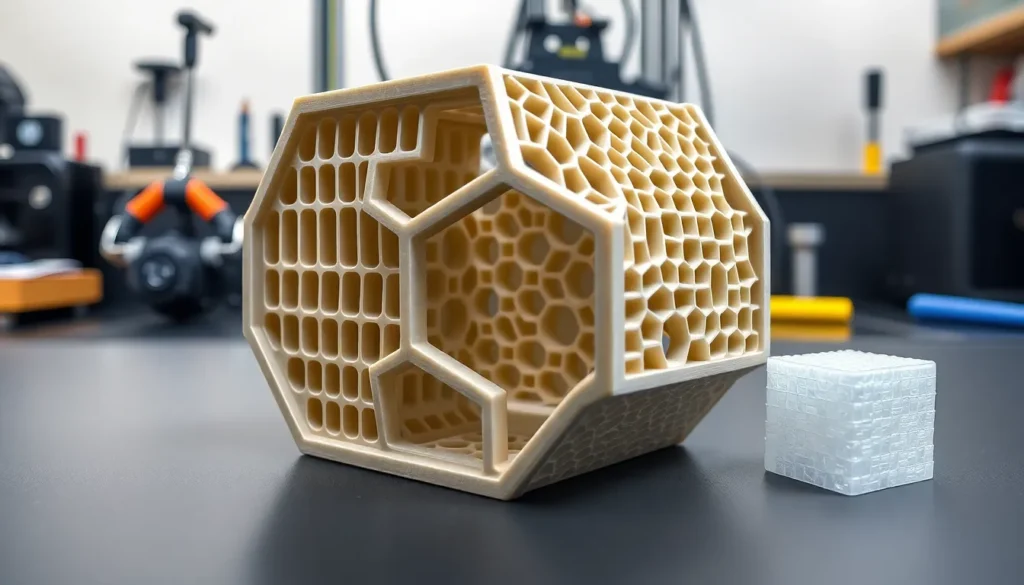

Type of 3D Printer

The type of 3D printer significantly affects the overall costs. Home models can start at around $200, whereas industrial-grade printers exceed $10,000. FDM (Fused Deposition Modeling) printers typically offer affordability and accessibility. SLA (Stereolithography) printers, known for their high-resolution outputs, come at higher price points. DLP (Digital Light Processing) printers serve niche applications, often incurring substantial investment. Users should evaluate their printing requirements to determine which type aligns best with their budget.

Quality of Materials

Material quality plays a crucial role in the costs associated with 3D printing. Standard filaments like PLA and ABS range from $20 to $50 per kilogram, providing budget-friendly options. Higher-quality materials, such as nylon or polycarbonate, can exceed $70 per kilogram, impacting the project’s overall expenses. Specialized materials for specific applications or industries may incur even higher costs. Users should assess their project’s demands to choose materials that balance quality with cost-effectiveness.

Comparing 3D Printing Costs

Understanding the differences between in-house 3D printing and outsourcing helps in making informed financial decisions.

In-house 3D Printing vs. Outsourcing

In-house 3D printing offers control and flexibility, enabling users to create prototypes and final products on demand. It involves upfront costs for a printer and materials but reduces long-term expenses for repeated or small-batch production. Outsourcing, on the other hand, typically incurs costs based on project complexity and volume. This method provides access to advanced technology and expertise not available in-house, which may justify higher per-item costs. Each option suits different business needs, so evaluating intended use and budget can guide operations.

Cost Comparison with Traditional Manufacturing

3D printing costs often differ significantly from traditional manufacturing methods. Initial investment for 3D printing may seem high, but it eliminates many costs associated with tooling and setup typical in traditional manufacturing. For small production runs, 3D printing provides substantial savings as it avoids large bulk order requirements. Traditional methods generally require lower per-item costs at scale, but their rigidity can limit flexibility. Businesses should consider production volume and design complexity when deciding between 3D printing and traditional manufacturing.

Tips for Reducing 3D Printing Costs

Reducing costs in 3D printing requires strategic planning and thoughtful decision-making.

Optimizing Designs

Start by simplifying designs to minimize material use. Reducing unnecessary features allows for less filament consumption, leading to overall savings. Adjusting the model with lighter infill can significantly decrease the weight and material without compromising strength. Using software to analyze and optimize designs ensures efficient use of resources. Finalizing a design that meets both aesthetic and functional needs aids in keeping expenses low.

Sourcing Affordable Materials

Prioritizing cost-effective materials enhances budget management. Research various suppliers for competitive pricing on filament. Standard materials like PLA and ABS often offer affordability without sacrificing quality. Buying in bulk can further reduce costs, making it favorable for larger projects. Considering recycled filaments can provide both eco-friendly solutions and savings. Choosing the right supplier ensures access to reliable materials without exceeding budget constraints.